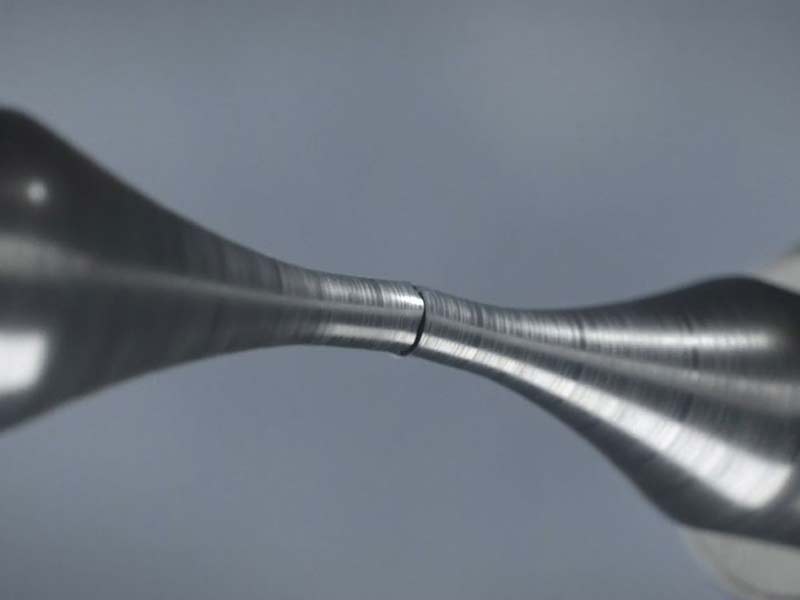

Ovako has a long experience from steels used for optimizing Power Density in Powertrain, based on more than a century of close product development for bearings applications.

Steel for rotating and reciprocating parts in engines and transmissions is our core strength. Ovako also enjoys a particularly strong position in steel for highly pressurized fuel injection components and we have advanced solutions that will benefit the higher rpm of E-drive systems. The Ovako prototype and material analysis capabilities can contribute to several months of lead time reduction for powertrain system development.

All steel grades from Ovako can be made with different cleanness levels, ranging from conventional steels to BQ-Steel level, and up to IQ-Steel. This means that Ovako can be a supplier for all sorts of fatigue resistance needs, where the IQ-Steel level is on the same performance level as the more expensive remelted steels. In addition, one can also benefit from the combined effect of clean distortion resistant steels for components with complex geometries. With Hybrid Steel, Ovako can offer particularly high performing solutions for elevated temperature, up to three times the strength of conventional steels.

Steel for powertrain is a large portion of the engineering steel market, and Ovako is active in many parts of it, from applications with more basic demands on the steel to advanced and demanding niches. With three metallurgies and different starting formats for rolling, Ovako is well suited to cater for demands from across the range of powertrain needs. This also includes marine and industrial powertrain, such as Wind power gearboxes.

In addition to the Ovako range of products, the Nippon Steel Corporation Group offers a wide range of additional supply capabilities.

We made it! But we are still not satisfied

What a journey! It took years of hard work to make our steelmaking operations more sustainable. In 2022, we went carbon neutral in all operations. But we´re still not satisfied - our journey towards steel production without CO2 emissions continues.

Read more about our path to carbon neutrality