The Impact of heating and cooling on steel properties

The heating and cooling processes involved in producing steel have a significant influence on its properties. These processes drive transformations in the various crystalline phases that make up the steel’s microstructure.

Dilatometry is a powerful research technique for studying phase transformation behavior. It enables real-time monitoring of transformation by measuring the minute dimensional changes that occur during specific heating and cooling cycles.

How high-speed dilatometry works

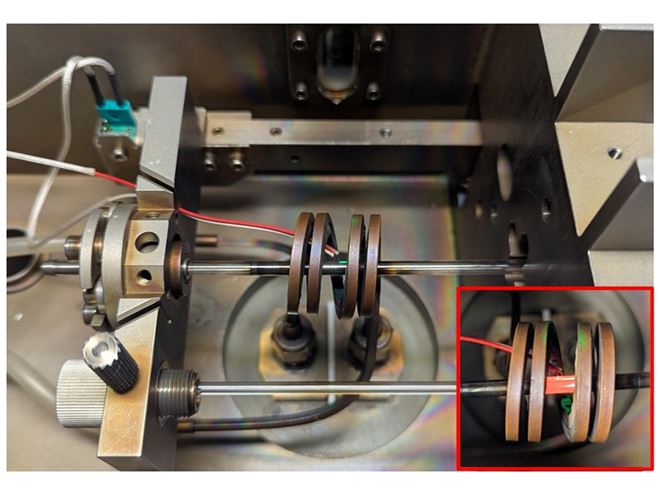

In a high-speed dilatometer setup:

- A thermocouple is spot-welded to a steel specimen to measure and control temperature.

- The cylindrical steel specimen is placed inside an induction heating coil, which generates a magnetic field that induces currents in the specimen, causing it to heat up.

- High-pressure gas jets provide rapid cooling.

- A frictionless rod transmits dimensional changes to an electronic transducer, while an optical system monitors the steel sample’s diameter.

This combination of induction heating and controlled gas cooling enables accurate measurements of phase transformations.

Phase transformation behavior in low-alloy engineering steels

Low-alloy special engineering steels, such as those produced by Ovako, exhibit distinct behaviors when subjected to heating and cooling:

- During heating below 700°C, the steel expands due to interatomic forces. However, upon reaching a critical temperature, it begins to contract as the crystal structure changes, forming the austenite phase.

- During cooling from high temperatures, austenite contracts as the temperature decreases. The steel then expands when it transforms into low-temperature phases such as ferrite, pearlite, bainite, or martensite.

Understanding these transformations is crucial for optimizing steel properties through heat treatment.

Optimizing steel properties with dilatometry

By combining precise temperature control with accurate dimensional measurements, dilatometry enables engineers to study transformation behavior in both new and established alloys. These insights help Ovako develop advanced heat treatment cycles that:

- Enhance steel properties

- Improve energy efficiency

- Reduce CO₂ emissions

Partner with Ovako for advanced steel solutions

Looking to optimize your steel’s performance through cutting-edge research? Contact Ovako today to learn how our expertise in dilatometry can help you achieve superior results.