Why clear definitions matter in the 'green steel' debate

Green steel is generating a lot of media buzz, but just what does that really mean? What factors should customers consider for sustainability? Vendela Stenius, Ovako’s Sustainability and Communications Specialist, explains why we ground our claims in hard facts and never actually talk about “green steel”.

Sustainable steel. Carbon neutral steel. Green steel. These are all the terms you often hear from the steel industry and read in the media. However, let’s face the uncomfortable truth: there is currently no universally accepted definition for “green steel”. This serves as a smokescreen, when what our customers really need is absolute clarity, not least so they don’t in turn confuse their own customers.

With this comes the risk of greenwashing and possibly tarnishing the reputation of the industry. Therefore, it’s important that players in the steel industry show existing and future potential customers exactly how they are removing carbon from their steelmaking processes and across their wider business.

Unmasking green steel myths

As Kermit says, it’s not easy being green. When it comes to green steel labeling, the scope and boundaries of product declarations are often unclear. But to prevent greenwashing, the product’s life cycle stages should be considered as well as assessing the climate impacts of its production.

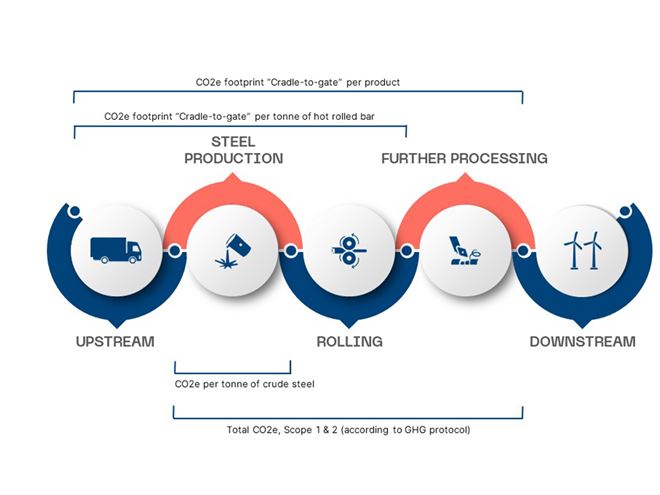

For example, at Ovako we present the “cradle-to-gate” carbon dioxide equivalent (CO2e) emissions per tonne of steel product that we deliver to our customers. This gives customers a complete picture of direct and indirect emissions of the product so they can make more environmentally conscious procurement decisions.

However, many steel suppliers exploit the vague terminology in their marketing to project an environmentally friendly image. Some fail to disclose comprehensive emissions data or sufficiently prove the “greenness” of their products, measuring only the direct carbon footprint of their steel production. This selective information sharing masquerades as environmental responsibility while potentially concealing dirty secrets.

Conflicting standards from various steel players also create a fertile ground for misleading claims, further muddling the industry’s reputation. Customers must demand full transparency – insisting suppliers disclose a product’s cradle-to-gate emissions, and possibly how the product might cut emissions in the next level of trade - not just cherry-picked metrics.

Peel back the layers on green steel claims

When sourcing a supplier, customers must scrutinize the “green steel” label beyond face value. They should demand evidence – detailed reports, case studies, and verifiable figures – that proves suppliers aren’t merely playing marketing games. At Ovako, rather than rely on empty marketing slogans we back our words with hard data. That means we focus on providing our customers with exact figures for the CO2 generated for each kilogram of delivered product.

Regardless of the categorizations,absolute terms minimizing this CO2 footprint is the only thing that matters for the planet. So, while a mass balancing solution, in which suppliers carve out their best CO2 emissions in a product line, might look good in marketing terms, it may not actually be addressing climate change as the overall emissions could be unchanged. It is therefore crucial to be always be extra cautious when using a mass balancing solution to ensure that it results in additional net CO2e reductions. This calls for gathering sufficient evidence to make sure that such a solution really is approved under corporate CO2e accounting principles.

That is why we have adopted a rigorous “cradle-to-gate” approach, offering a thorough environmental impact assessment from resource extraction (cradle) to the factory gate, before reaching the customer. This method ensures a complete and honest accounting of our environmental footprint, sidestepping the selective reporting and misleading metrics others hide behind. At Ovako, we lay it all bare – because the truth demands it.

Our cradle-to-gate approach includes comprehensive life cycle assessments for delivered goods, going beyond CO2e per ton or scope 1 and 2 emissions. In essence, we don’t use any mass balancing solutions, we simply provide data on the kg of CO2e generated per tonne of delivered goods.

With this approach, customers can compare the CO2e indicator for the steel we supply. They can also combine all the indicators for various materials and services they use to determine the overall carbon footprint of their end product. This helps prevent greenwashing in what we say to customers.

A genuine sustainability roadmap

Ovako is not just about high-flying rhetoric; our actions back up our claims. For instance, we’ve converted our heat treatment furnaces to electricity and purchase fossil free Nordic electricity. We have also developed a supply chain that sources high quality scrap and have installed energy efficient systems.

It doesn’t stop there. In September 2023, we welcomed a new addition to our Hofors mill as part of the next steps in our decarbonization journey: a hydrogen production plant. The plant produces fossil-free hydrogen to fuel our steel heating furnaces. This helps reduce emissions from our rolling mill to almost zero.

Putting transparency at the core of sustainability

Transparency is not just a buzzword; it’s the bedrock of genuine sustainability. But how do we make circularity and carbon emissions at the forefront of our products – and how do we truly work with them to deliver better performance? There are no definitive answers as there are no official standards in this area, but Ovako has outlined several important elements we embrace to help tackle these challenges.

Firstly, we aim to collaborate with our customers as much as possible, making the best use of resources to improve our products, circular flow, and reduction targets. We have also gained a better understanding of what’s required by who, and when to invest and deliver products accordingly.

Measuring our emissions is also important. By declaring the carbon footprint of a specific product from cradle-to-gate, customers can compare products and assess the footprint of their end products. At Ovako, we have developed a Carbon Calculator tool that helps customers precisely evaluate the CO2 emissions of the steel products they are buying.

Our Carbon Calculator closely monitors each stage in the production and transportation of steel products, calculating the carbon footprint for each product in kg CO2e per ton of steel. With this, customers can compare products – as well as supply their own customers – with the vital data that helps them make more meaningful comparisons between suppliers. This level of transparency enables comparisons that focus on meaningful, environmentally conscious decisions rather than superficial green labels.

Moving beyond greenwashing in steel

The vague definitions and conflicting standards around “green steel”, even when well meaning, contribute to a lack of clarity, which helps no one. Customers must demand real accountability, insisting on detailed, verifiable evidence of genuine sustainability from their suppliers. It’s time to strip away the false pretences and expose the reality, ensuring that the steel industry meets its environmental promises with tangible, transparent action. Only then can we curb greenwashing and build a truly sustainable future.

Contact your local sales team to request an emissions report from Ovako today