Fatigue failure generally results from the accumulation of microplastic deformation under repeated cyclic conditions. By “microplastic” I mean microscopically small areas of the component where the material is subject to plastic deformation while the bulk retains its elastic properties.

This type of failure affects the service life of a wide range of machine components, such as gears, rolling bearings, and camshafts. Rolling bearings, particularly those operating under elastohydrodynamic lubrication, undergo alternating contact stress within a small area. This gives rise to subsurface damage known as rolling contact fatigue (RCF), causing microstructural changes beneath the contact area that ultimately manifests as fatigue damage.

Previous research work has investigated the microstructural decay resulting from RCF, with a focus on the most common bearing steel, grade 52100. The microstructure of 52100 steel comprises tempered carbides, residual cementite (RC), and a martensitic matrix. Forms of microstructural decay identified during RCF include the formation of dark etching regions, white etching bands, and carbide dissolution (RC and tempered carbides). This decay becomes apparent after a high number of stress cycles, leading to a decrease in hardness and a subsequent degradation of the bearing’s functionality.

The ability of a material to withstand RCF depends largely on its composition and heat treatment. In particular, materials that resist softening can extend the lifespan of bearings.

In recent years, Ovako has introduced Hybrid 60 steel, a novel grade combining secondary hardening and intermetallic precipitates. It was developed to overcome the limitations of existing materials, particularly in bearing applications subject to challenging operational conditions such as in corrosion and hydrogen environments. However, a more comprehensive understanding of how it behaves under RCF is crucial to predict its response to cyclic loading. Investigating this was the basis for my thesis, with the aim of identifying how Hybrid Steel 60 decays under RCF.

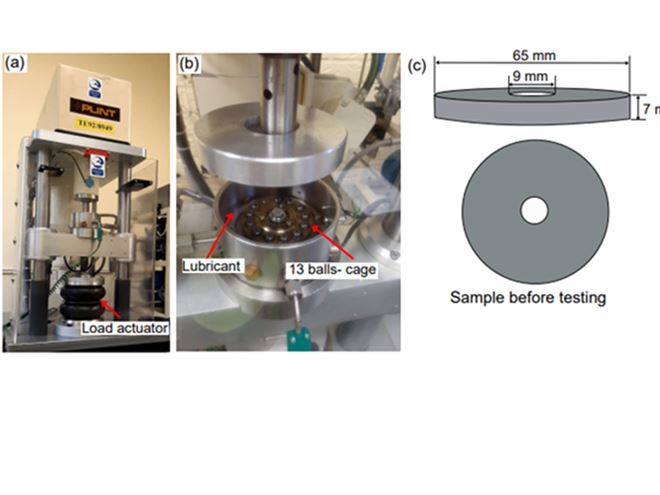

We used a microprocessor-controlled flat washer test rig, as shown below, to subject samples of 52100 and Hybrid Steel 60 to different RCF loadings. This setup has a 13-ball configuration in which the washer-like sample is positioned over the lower raceway. The 13 silicon nitride balls are contained in a cup that serves as the outer race of the bearing. These balls rotate to create a circular contact track on the top surface of the sample.

The test was stopped after a predetermined number of cycles and the samples were then evaluated with a variety of advanced characterization techniques.

For both steels the results revealed distinct microstructural alterations in the region of maximum shear stress beneath the raceway surface. These alterations include the presence of ferrite microbands, dissolution of carbides and precipitates, and the formation of nano-ferrite grains.

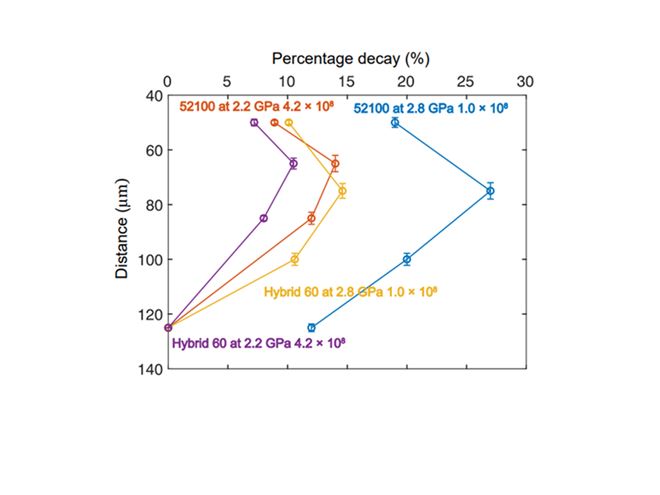

The most interesting result is that Hybrid Steel 60 had less microstructural decay after the same number of stress cycles (1.0 × 108) compared to 52100 steel, as illustrated in the graph.

This difference can be ascribed to the effect of precipitates in Hybrid Steel 60 that enhance its resistance to softening.

Conclusions and future work

The results of this test program suggest that Hybrid Steel 60 is better suited for special bearing applications where corrosion and hydrogen resistance are required, as 52100 does not offer these additional properties. However, future work is needed to clarify the relationship between microstructural decay and fatigue crack initiation.

Another area of important research will be Tribo-corrosion fatigue testing to evaluate the impact of water-based lubricants that could potentially emerge as the leading environmentally friendly lubricant in a wide range of applications, including electric vehicles (EVs) and offshore applications.

Further reading. To discover the full results of this research program, as well as references to other work and a bibliography, please refer to my doctoral thesis:

“Microstructural Decay in High-Strength Bearing Steels under Rolling Contact Fatigue”