“Industry is facing a challenge from growing lead times for remelted steel”, says – Stefan Czeczor, Dip -ing. Manager Technical Customer Support. Stefan continues “in some cases, suppliers are quoting lead times of two years, with a minimum order quantity (MOQ) of 20 tonnes or more and with no flexibility to vary order quantity or dimensions.”

This represents a major risk for manufacturers of bearings, rollers, gears and high-performance components for mining and industrial motion. They rely on remelted steel to avoid metal fatigue in demanding applications that need material to provide the same mechanical performance under complex dynamic loading from different axes.

As the production capacity for remelted steel is limited, it is worth looking for an alternative solution. OEMs typically buy remelted steel as it is required under long-standing technical specifications. These are well-proven but are often based on standards that were written 60 years ago.

Steelmaking has transformed in this time. As a producer of ultra-clean steel, we can deliver air melted steel that matches the performance of remelted steel.

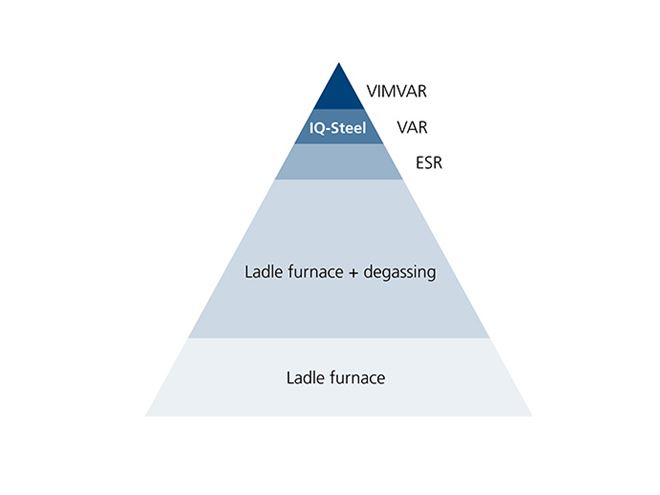

Our IQ-Steel has comparable fatigue strength, machining experience and heat treatment response as remelted steels produced under the electroslag remelting (ESR) and vacuum arc refining (VAR) processes. This creates an opportunity for OEMs to specify IQ-Steel to overcome risk in the supply of remelted steel and shorten lead times.

Helping our customers build a case to challenge the specifications

An important barrier to adopting an alternative material is that remelted steel is often included in the technical specifications required by customers or their end customers. Even though IQ-Steel has similar properties, OEMs need to engage their customers and then build a technical case to challenge the requirement for remelted steel in the specifications.

At Ovako, we can provide a starting point for this in the form of data from out our own laboratory testing. We found there is close alignment in the mechanical properties between IQ-Steel with ESR and VAR steels. The most significant difference we identified was visual appearance under the microscope due to a difference in micro segregation between the samples. However, as metallurgists, we know that our customers will always need to perform their own independent testing and evaluation.

To support this, we can provide samples of material for our customers to test.

Download our technical report in IQ-Steel for critical applications

MOQ, price and carbon footprint

Aside from similar performance and lower lead time, our IQ-Steel offers advantages over remelted steel. Depending on the dimensions, we accept orders as small as 5-10 tonnes. This is a lot lower than the MOQ of 20-30 tonnes for remelted steels. It will also offer a significant price advantage over remelted steel.

In addition, IQ-Steel will always have a lower carbon footprint than remelted steel. The second melting process will always have a bigger environmental impact than a single melt, even if the remelted steel mill sources zero-carbon electricity like we do.