High-Performance Hollow Bar for Demanding Applications

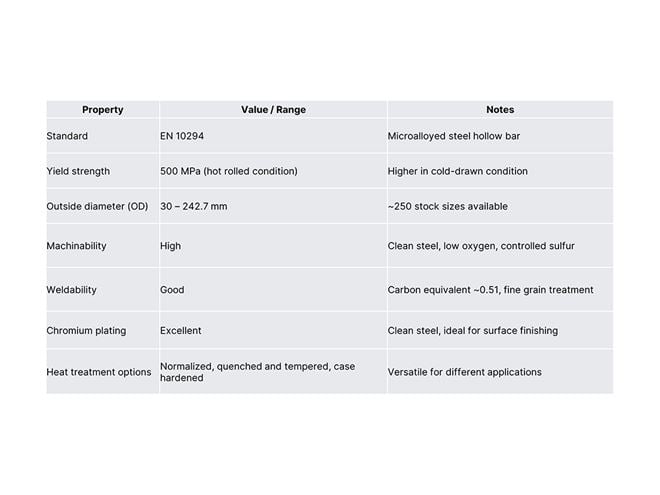

Ovako 280 Hollow Bar is a microalloyed steel product based on the EN 10294 standard, designed for high strength, machinability, weldability, and chromium plating. Developed as an off-the-shelf solution, it offers consistent performance thanks to the same clean steelmaking processes used for Ovako bearing steels.

With more than 250 stock sizes available, Ovako 280 Hollow Bar reduces machining time and material waste, helping manufacturers increase productivity and lower costs.

Applications of Ovako 280

Thanks to its versatility, Ovako 280 Hollow Bar performs reliably in a wide range of mechanical and industrial uses, including:

-

Hydraulic cylinders

-

Injection molding machines

-

Machine tools

-

Printing rollers

-

Transmission elements

-

Bushings and couplings

-

Electric motor spindles

-

Shafts and axles

Key Advantages

-

High strength in hot rolled condition, up to 500 MPa yield strength

-

Cost-effective alternative to quenched and tempered steels

-

~250 stock sizes available, OD 30–242.7 mm

-

Good machinability and tool life thanks to low oxygen and controlled sulfur

-

Weldable without preheating in most cases

-

Excellent surface for hard chromium plating

-

Dimensional stability during quenching, tempering, and case hardening

Product Performance Options

Ovako 280 Hollow Bar is available with several heat treatment options to suit different industrial applications. In the cold drawn condition, it delivers even higher strength for demanding environments such as hydraulic cylinders and machine tools. The normalized condition is recommended where components need reliable impact strength at low temperatures, for example in shafts and transmission elements.

For applications that require very high tensile strength and hardness, Ovako 280 can be supplied in the quenched and tempered or case hardened condition, offering excellent dimensional stability with predictable changes during processing. These flexible performance conditions, based on the EN 10294 standard, make Ovako 280 a versatile choice for manufacturers seeking consistent quality and productivity.

Why Choose Ovako 280 Hollow Bar

-

Reliable, consistent performance batch after batch

-

Proven production economy with reduced machining waste

-

Suitable for high-precision applications across multiple industries

-

Manufactured with strict quality control for clean steel

Steel Navigator - Find the right steel for your application

Steel Navigator contains a selection of useful tools such as Material Data Sheets, Machining Cost Calculator, Heat Treatment Guide, Piston Rod Predictor and more.